Provide your client innovation with SteelX

INTRODUCTION TO STEELX

Understanding Twisted Steel Rebar

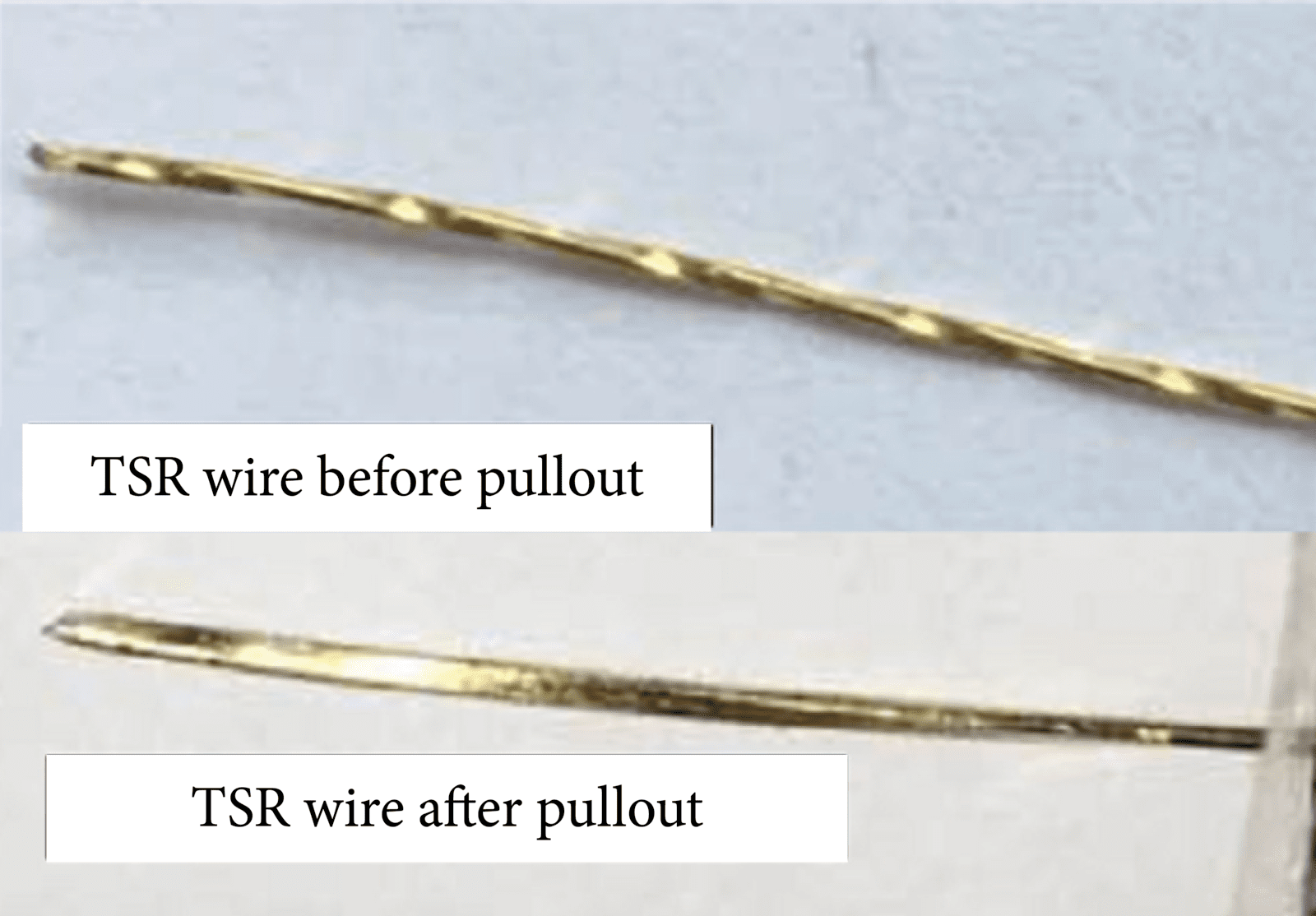

SteelX 5:25 Gold is Twisted Steel Rebar (TSR) that has a unique ability to bond with concrete due to its twisted shape, providing a torsional anchorage that engages before the concrete fails and that creates a true composite with the concrete.

Each piece of SteelX bonds to the matrix over its full length and must untwist as it pulls out of the concrete. This is significantly different from steel fibres where pullout is governed by friction.

Due to the superior bond of SteelX, the material properties of the concrete are improved prior to a crack forming i.e. SteelX provides proactive reinforcement. After a crack forms, SteelX provides a stable capacity allowing engineers to design just like rebar.

SteelX 5:25 can provide significant cost savings to your clients by removing mesh and rebar, reducing pavement thicknesses, cutting project schedules and improving site safety.

Your client can also save by the removal of the need for concrete pumps, reduced risk of weather-related delays and removal of steel fixing, steel deliveries and set down areas on site. Most importantly, the unique performance of SteelX provides your client with a stronger, more durable solution.

Properties of SteelX

SteelX enhances the material properties of concrete in three ways.

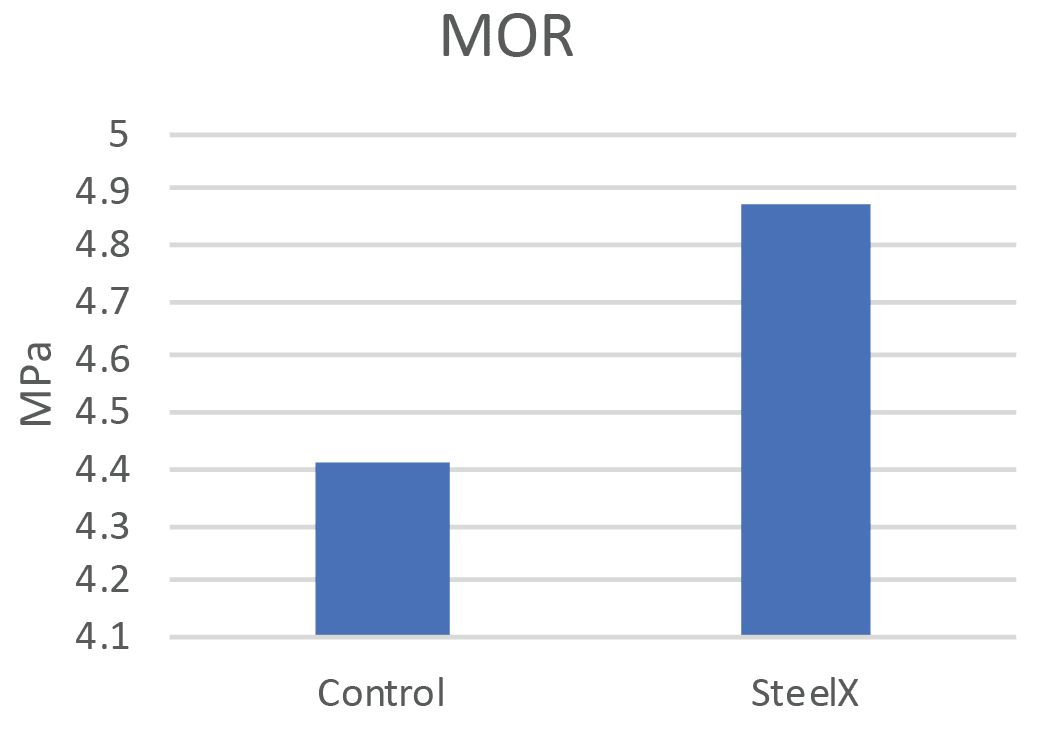

Increased Modulus of Rupture (MOR)

SteelX increases the concrete’s First Crack Strength (MOR).

Increased Strain at First Crack

Twisted Steel Rebar not only increases the load at first crack, it also increases the amount of strain the concrete can carry prior to crack formation. This means TSR concrete is more ductile and flexible.

Increased Tensile Splitting Strength

Twisted Steel Rebar can improve the tensile splitting strength of concrete. Testing shows that even with relatively small dosages of TSR, significant improvement is achieved.

(Data from TSR product published in paper titled "Mechanical, durability and microstructural characteristics of ultra-high-strength self-compacting concrete incorporating steel fibers" by Amr S. El-Dieb. Date 1 April 2009.)

These advantages can be overlooked when designing reinforced concrete with SteelX 5:25, however they are real and tangible and should be recognised for the material benefit that they add to the long-term serviceability and durability of the concrete structure.

SteelX gives your client so much more!

Design Principles of SteelX 5:25

The SteelX design approach is outlined in our Design Manual. To receive a copy of our design method please email us at info@steelxrebar.com.au

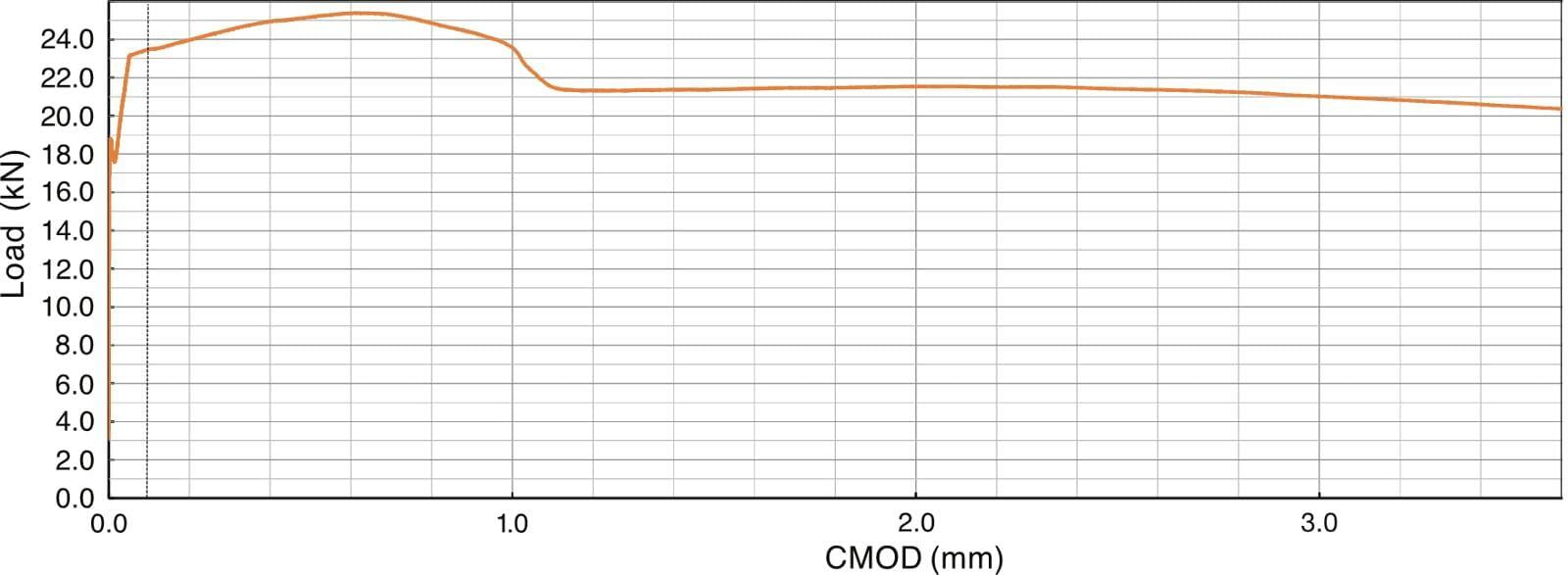

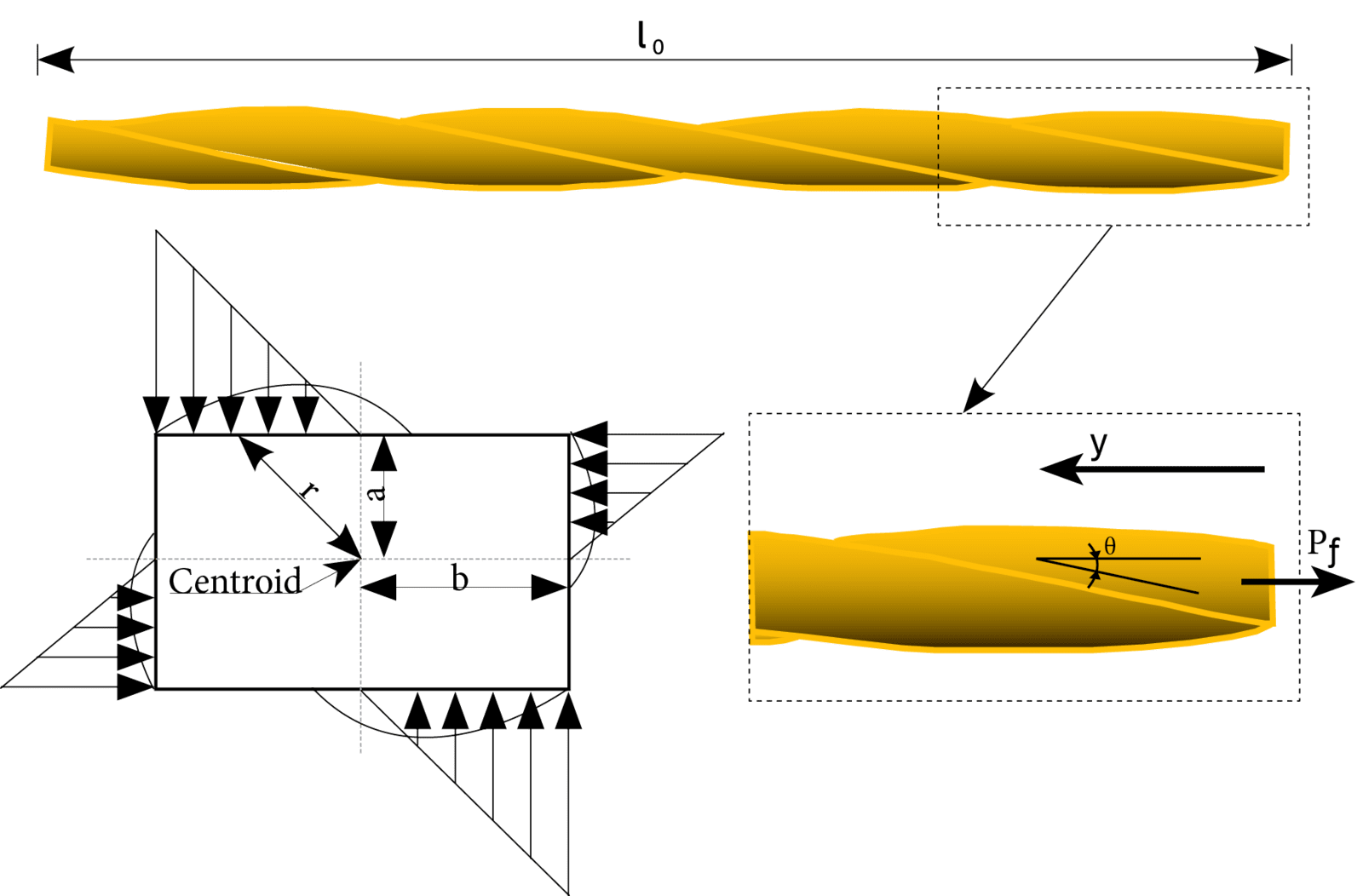

The tensile resistance of SteelX is developed from its bond and the unwinding of the twists in each piece. Since the SteelX must stretch and untwist before it can pull out of the concrete, it provides constant tensile resistance regardless of strain up to 1%.

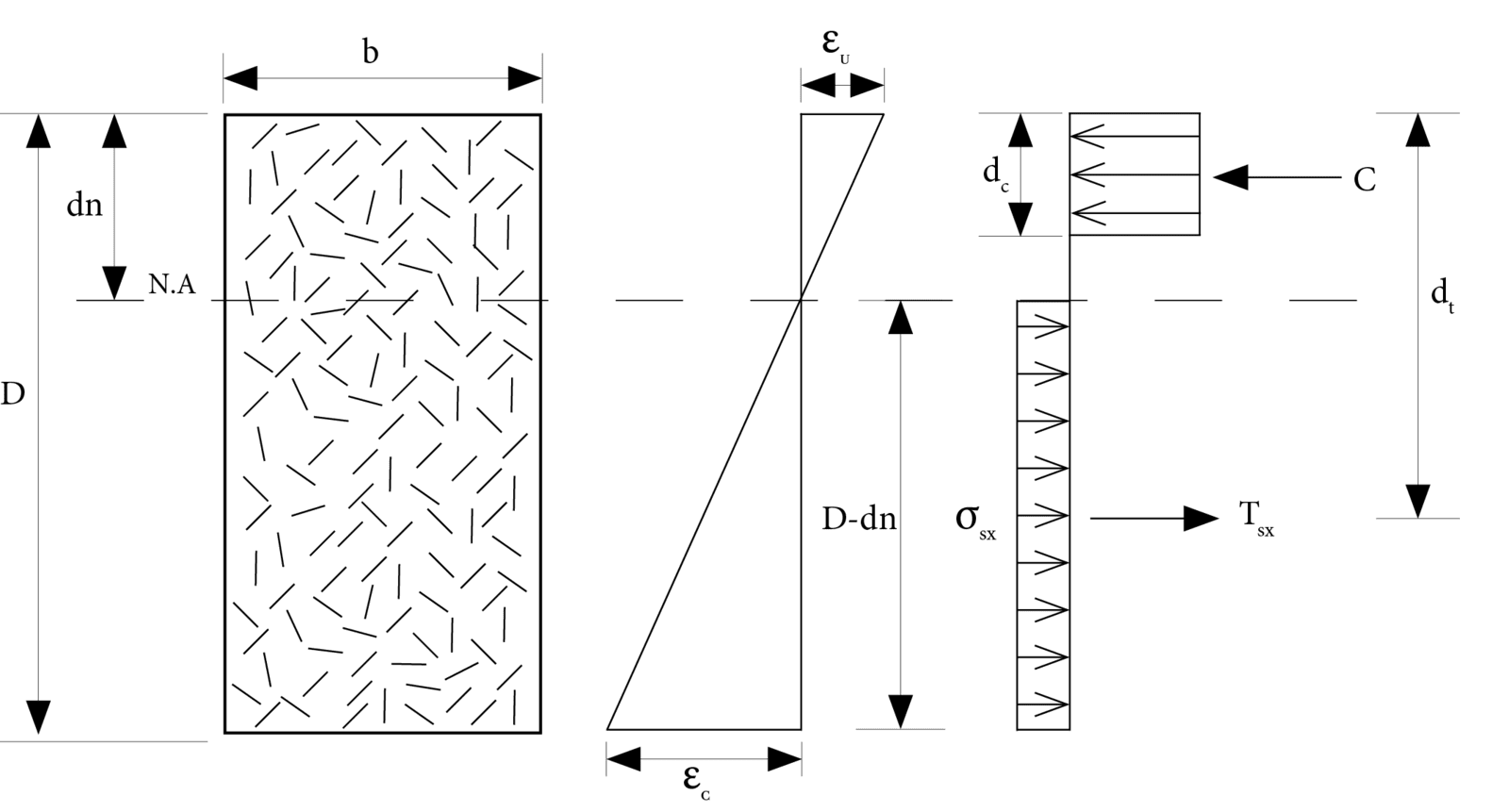

Fig. A - Cross section diagram of a rectangular Twisted Steel Rebar showing the torsional untwisting force applied to pullout a SteelX Rebar.

Using the force equilibrium and strain compatibility approach that engineers employ when designing a reinforced concrete section, the same approach is applied when designing a SteelX reinforced concrete section. SteelX can be designed using a rectangular stress block for the entire area in tension.

Design Classes

The Design Method adopts ‘Design Classes’ based on the consequence of failure and uses the tried-and-true LRFD (Load and Resistance Factor Design) method for deriving resistance factors and producing safe and reliable designs.

Design Classes are:

Class ST: Shrinkage and Temperature

Class S: Supported Structural Reinforcement

Class U: Unsupported Structural Concrete

In addition to the LRFD method, the Design Method employs additional redundancies to ensure stability for any structural concrete application. These include one or more of the following;

For Design Classes ST and S:

- Full support

- Geometric support in the case of lateral structures i.e. walls

- Strain limits to keep the section in a pre-crack environment

For Design Class US:

- Conventional rebar – for unsupported horizontal or cantilevered concrete.

X-Factor design

SteelX provides a stable tensile force that increases linearly based on dosage. To make it simple to design with SteelX, engineers can use a multiplier (the X-Factor) to convert the reinforcement ratio to a SteelX dosage. The Dosage is equal to the reinforcement ratio multiplied by the X-Factor.

The X-Factor is calculated as a function of the tensile strength of SteelX verse the conventional steel being replaced on a weight to volume basis, then converted into a multiplier of the reinforcement ratio.

To learn more about designing with SteelX please contact us for free training.

SteelX Liberty™ Slab - Freedom from joints

Introducing the LIBERTY™ slab

The SteelX LIBERTY™ jointless slab system is the next step in concrete slabs. SteelX LIBERTY™ can be applied in any situation that requires fewer joints, minimal cracking, less maintenance and next-level durability.

This new slab design removes the need for saw cut joints while reducing the slab thickness by 20%. Construction joints are governed by what can safely be poured and finished by the concrete contractor and not by restraint, posts or typical joint spacing.

Why was the LIBERTY™ slab created?

We saw a gap in the industry for a cost effective & durable jointless concrete slab that was easy to pump and finish. Thus, SteelX LIBERTY™ was born.

Besides the aesthetic burden that joints carry, other issues such as large cracks, excessive maintenance and low durability, all contribute to the growing need for a reliable jointless slab design.

SteelX LIBERTY™ reduces these burdens and the problems they cause, including the loss of production time for repairs and excessive ongoing maintenance costs.

Design Philosophy

The design philosophy behind the Liberty slab rests on three underlying foundations:

Liberty Slab Design examples

Drinks Manufacture - Heavy Load slab for Vats

Slab details:Slab 1 - 200mm thick - 20m x 6m - Tied on all sides, 3 drainage pit.

Slab 2 - 235mm thick - 33m x 21m - Tied on all sides, 1 drainage pit plus over 60 meters of drainage channel

Slab 3 - 150mm thick - 15m x 9m - Tied on all sides, 7.5 meter drainage channel.

Loading: all slabs were loaded with very large pits that applied large point loads.

SteelX Solution: All slabs were poured without any joints using a dosage of 23kg/m3 plus SL81 mesh bottom.

Freezer slab

Slab details: 150mm thick - 32m x 17.5m - minus 40 degrees CelsiusSteelX Solution: Slab poured without joints using a dosage of 18kg/m3 plus SL82 mesh centrally placed.

Sports court - jointless design to replace post tensioning.

Slab details: 150mm thick - 38m x 27m - restrained on 3 sides by an edge beamSteelX Solution: Slab poured without joints using a dosage of 18kg/m3 plus SL92 mesh, top.

Applications for the LIBERTY™ slab

» External pavements

» Wash-down slabs

» Post tension slabs on-ground

» Waterways

» Bunded & containment slabs

» Corrosive environments

» Basement slabs

» Waste facilities

» Hygiene floors

» Jacking slabs

Benefits of the LIBERTY™ slab

» Easy to pump

» Easy to finish

» No saw cut joints

» Reduced maintenance

» Increased durability

» Controlled crack widths

» Protective coating

» Reduced spalling and fraying

» No joint sealing

» Standard mesh sizes

Start specifying today with our Design Guidelines

Engineering training course

SteelX provide innovative in house training to engineering companies wanting to learn more about SteelX Rebar.