Twisted Steel Reinforcement

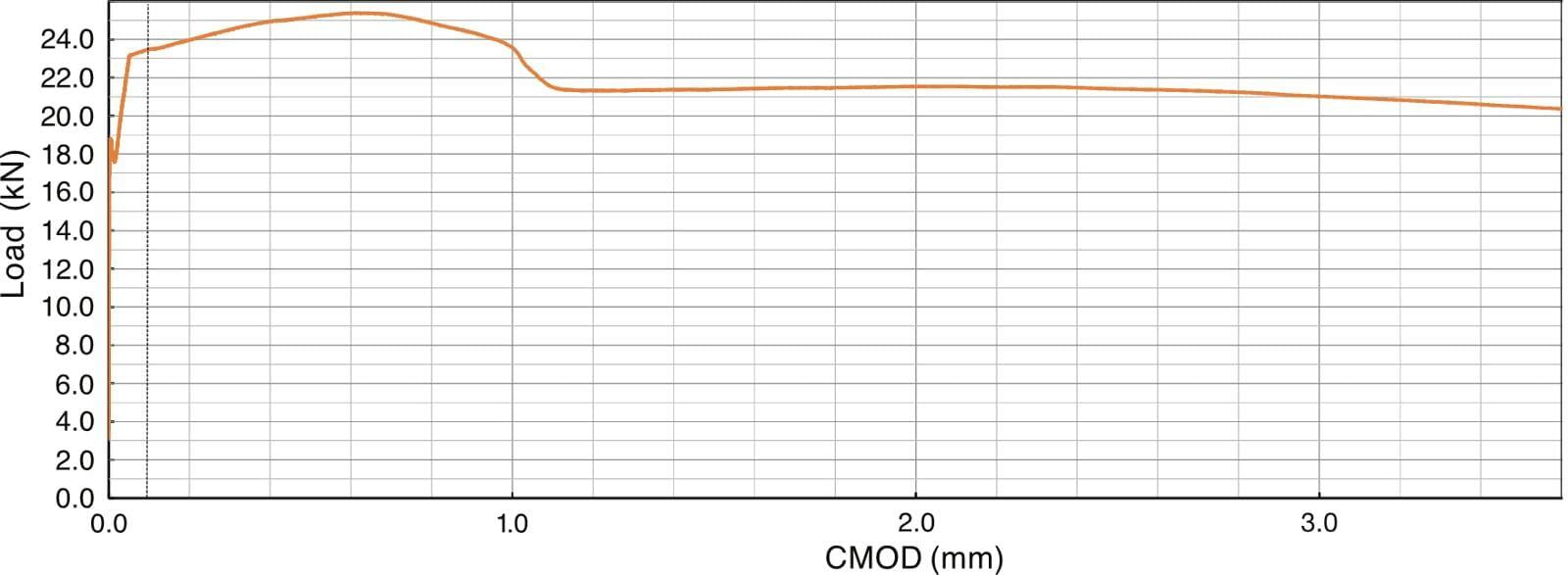

SteelX 5:25 is a Twisted Steel Reinforcement/Rebar (TSR) that has a unique ability to bond with the concrete due to its twisted shape, providing a torsional anchorage that engages before the concrete fails and that creates a true composite with the concrete.

Each piece of SteelX bonds to the matrix over its full length and must untwist as it pulls out of the concrete. This is significantly different from traditional steel fibres where pullout is governed by friction.

Due to the superior bond of SteelX products, the material properties of the concrete are improved prior to a dominant crack forming i.e. SteelX 5:25 provides proactive reinforcement. After a dominant crack forms, SteelX 5:25 provides a stable capacity allowing engineers to design just like rebar.

SteelX 5:25 products provides significant cost savings by removing mesh and rebar, reducing pavement thickness, cutting project schedules and improving site safety.

Twisted Steel Rebar not Steel Fibre

Many incorrectly assume that SteelX is just 'another' steel fibre.

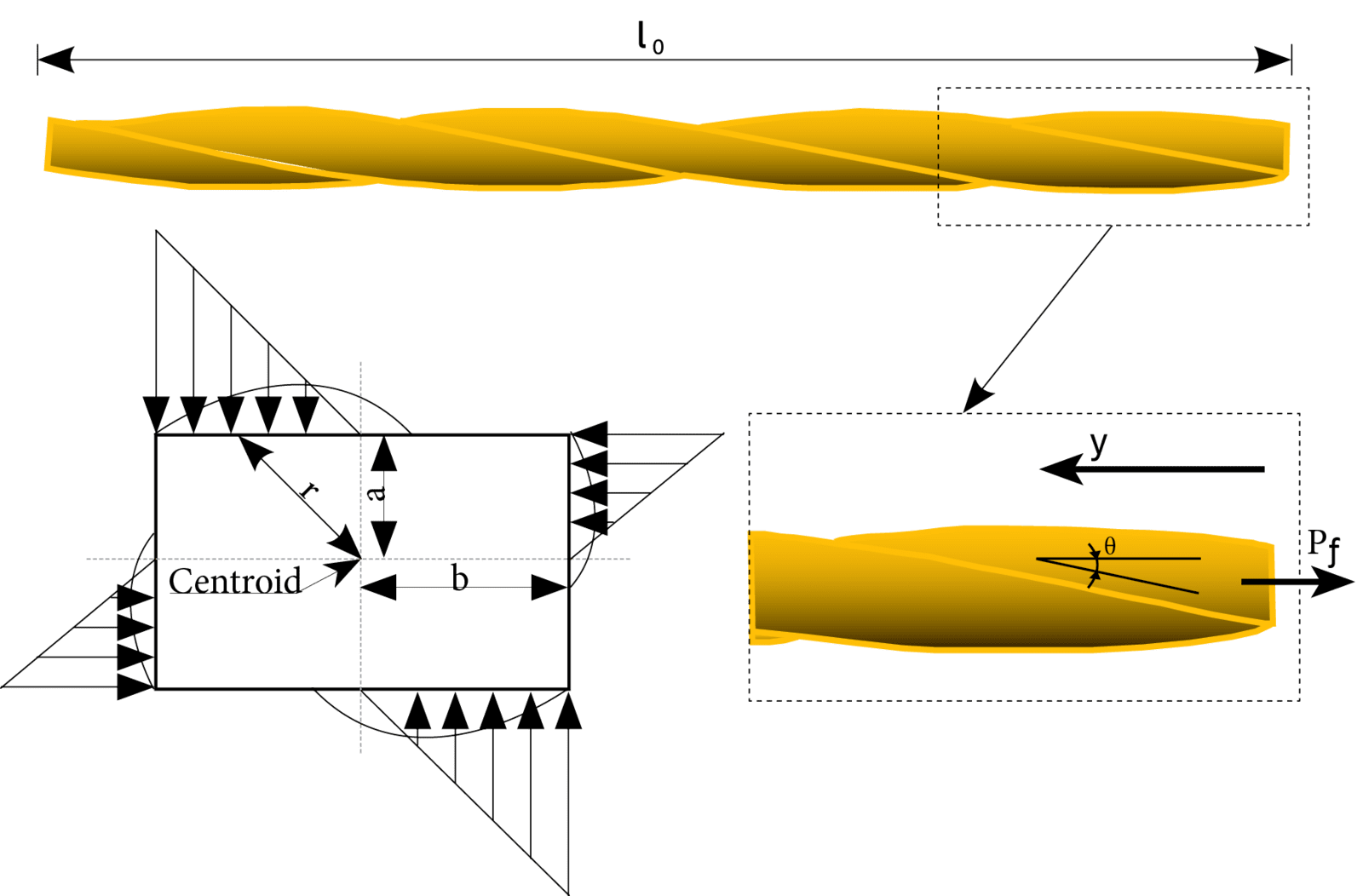

SteelX 5:25 must untwist to pull from the concrete which results in a torsion failure mechanism as apposed to bending or friction. Figure 1 shows the force diagram of SteelX 5:25 wire when being pulled from the concrete matrix.

Products

Our product is shaped to produce precise mechanical characteristics and we currently offer the following product to market.

SteelX 5:25 GOLD*

Length: 25 mm

SteelX 8:45

Length: 45 mm

About Us

McClay Industries Pty Ltd, trading as STEELX REBAR, is the most experienced distributor of Twisted Steel Rebar technology in the Australian market. With over 10 years of helping the construction industry pioneer the use of TSR we are the trusted face in the Australian market.

McClay Industries Pty Ltd was previously the Principle Agent for a different producer of TSR technology. During that time McClay Industries Pty Ltd, gained significant experience in our former role and we bring that experience to SteelX Rebar and our products.

With our experience, we are committed to finding you the best solutions for every project. Sometimes that means recommending more of our products, sometimes it mean less. What matters is that a great outcome is achieved from design to placement. We will be with you the whole way.

Key Facts of experience obtained in former role:

- First agent in Australia to sell Twisted Steel Rebar and longest serving by many years.

- First client was Rio Tinto.

- Out sold all other agents in Australia combined - made up roughly +30% of global sales.

- Trained over 50 engineering companies and over 200 engineers to specify Twisted Steel Rebar.

- Member of the AS3600 sub-committee of steel fibre reinforced concrete.

- Completed over 100,000m2 of walls in high rise construction with our clients.

- Completed hundreds of thousands of square meters of concrete slabs with our clients.

- Completed more structural concrete projects with TSR than anyone in the world.

- Developed majority of marketing material used in Australia.

- Developed new jointless slab design methodologies with TSR - See the SteelX Liberty™ Slab.

- Successfully worked hand in hand with engineers, concrete suppliers, concreters and builders.

- Built strong and lasting relationships.