Delivering Reinforced Concrete

SteelX is the reinforcement of choice for ready-mix batch plants. With improved concrete ductility, lower dosages, easy loading and excellent distribution throughout the concrete matrix SteelX is the first choice to offer your clients.

Batch

Batch Procedure

SteelX is the easiest product on the market to add, mix and record. Use the batching procedure to batch concrete agitator trucks.

Quality Assurance

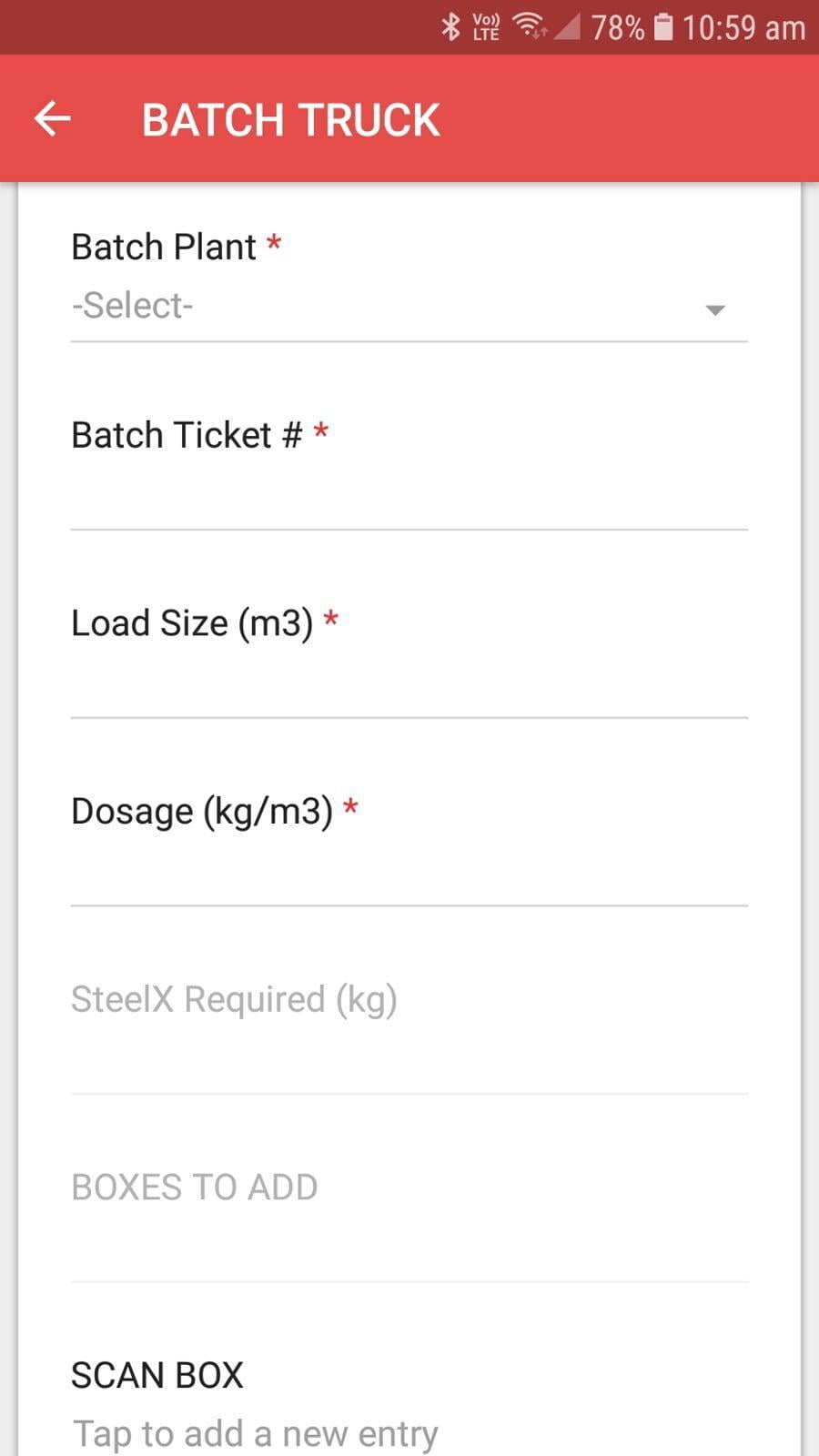

SteelX Live app

Go live with the SteelX Live app. You can now track every box that is added to the truck and the site can receive the load. Live QA end-to-end.

Online Quality Assurance

Track each load online with the SteelX Online Quality Assurance log.

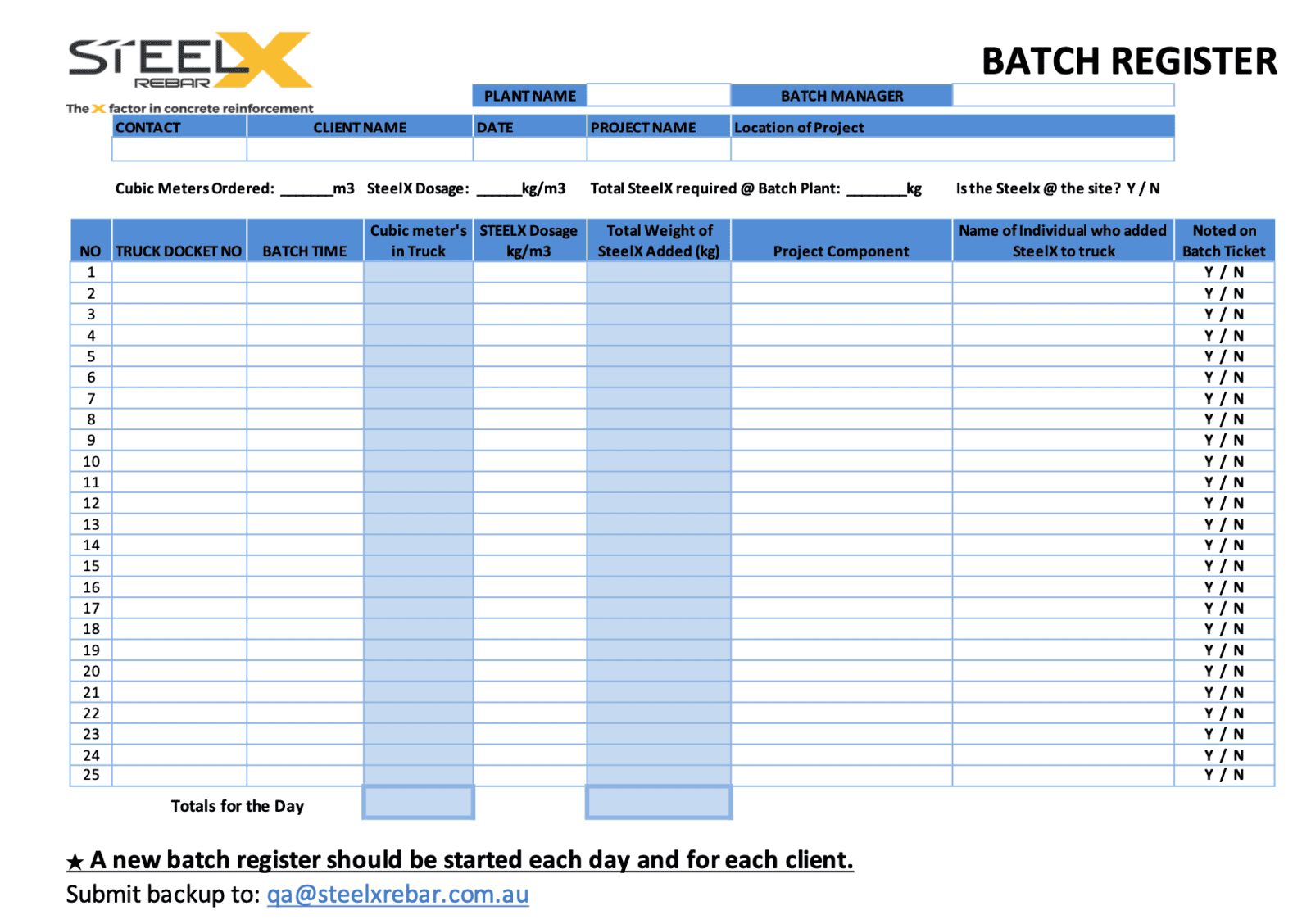

Manual Quality Assurance

Not ready to go live or online, then record each batched load on the paper based worksheet.

Mix Design Recommendations

Adding SteelX to concrete can have an impact on the slump and workability. It is important that the mix designer takes the addition of SteelX into account, making adjustments if required. The following information provides guidance on how to manipulate the mix design to account for the addition of SteelX.

Mix Design and Admixture Recommendations

If targeting a slump of 80mm, the following adjustments would be required based on the SteelX dosage:

- Dosages below 10kg/m3 - aim for a slump of 80-90 mm

- Dosages from 10-19kg/m3 - aim for a slump of 90-110 mm

- Dosages from 20-30kg/m3 - aim for a slump of 110-150 mm

Note:

- Water reducing admixtures are to be used to achieve these slumps (not additional water).

- Conventional mix designs may be used for dosages of 20kg/m3 or lower. For dosages greater 20kg/m3, the mix design (particularly w/c and fines ratio) require adjustment in accordance with AC1 544 SFRC* (Tables 4.1 and 4.2).

Class US Designs - Unsupported Structural Concrete

If the concrete has been designed as an Unsupported Structural Concrete application (Class U), the mix shall have minimum fine to total aggregate ratio of 0.50 to assure adequate bond with the SteelX and a minimum compressive strength of at least 30MPa.

Mix Design Reviews

Typically, a mix design requires minimal to no alterations when using SteelX. In most instances, a mix design that performs well without SteelX, will perform well with SteelX.

If you consider your project to be of a certain complexity, for example jointless slabs, partly restrained elements where crack widths are critical then please contact us for a free mix design review - info@steelxrebar.com.au.